OPTI-Measure is a specialized software tool designed to cater to the complex needs of the manufacturing and engineering industries, particularly in the realm of precision measurement and quality control. As industries evolve, the demand for highly accurate and reliable measurement solutions has grown significantly. OPTI-Measure stands out as a critical asset in ensuring that products meet stringent quality standards and comply with industry regulations.

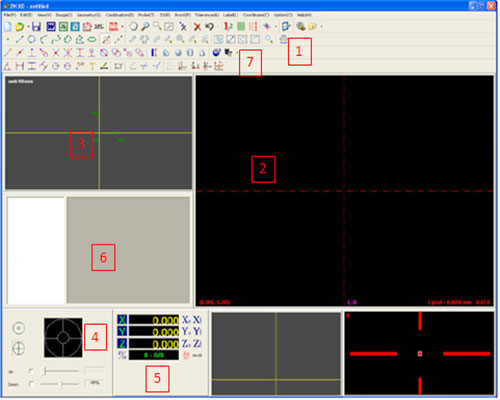

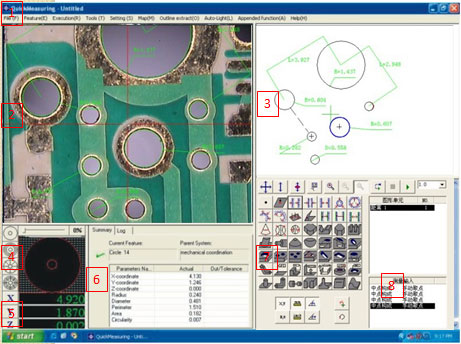

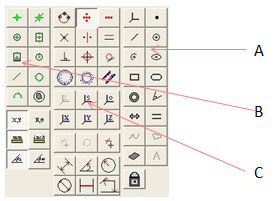

The software is designed to interface seamlessly with a wide range of measurement devices, including coordinate measuring machines (CMMs), laser scanners, and optical measurement systems. By integrating with these devices, OPTI-Measure enables the precise capture of dimensional data from manufactured parts, ensuring that every measurement is accurate and repeatable. This is crucial in industries such as aerospace, automotive, and medical device manufacturing, where even the smallest deviation from design specifications can have significant consequences.

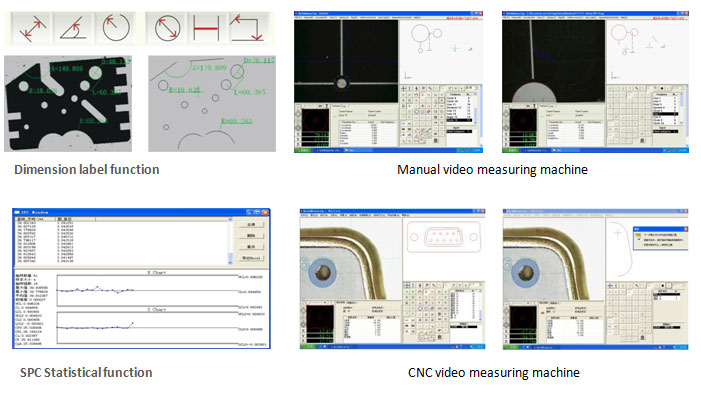

One of the key features of OPTI-Measure is its robust data analysis capabilities. The software not only collects measurement data but also processes it to identify trends, variations, and potential defects. This analysis is essential for manufacturers looking to maintain high levels of product quality and minimize waste. By identifying issues early in the production process, companies can implement corrective actions before defects become widespread, thus saving time and resources.

OPTI-Measure also excels in its ability to generate detailed reports and documentation. These reports are critical for maintaining compliance with industry standards such as ISO 9001 and AS9100. The software can automatically generate inspection reports that include all relevant measurement data, as well as visualizations such as graphs and 3D models. This not only simplifies the auditing process but also provides valuable insights for continuous improvement efforts.

In addition to its measurement and analysis capabilities, OPTI-Measure offers advanced features for statistical process control (SPC). By monitoring key performance indicators in real-time, the software helps manufacturers maintain tight control over their production processes. SPC features allow users to set control limits, monitor process stability, and detect any deviations from the norm. This level of control is vital in ensuring that products consistently meet quality standards and reducing the likelihood of defects.